LiftTiles: Constructive Building Blocks for Prototyping Room-scale Shape-changing Interfaces

Abstract

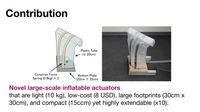

Large-scale shape-changing interfaces have great potential, but creating such systems requires substantial time, cost, space, and efforts, which hinders the research community to explore inter- actions beyond the scale of human hands. We introduce modular inflatable actuators as building blocks for prototyping room-scale shape-changing interfaces. Each actuator can change its height from 15cm to 150cm, actuated and controlled by air pressure. Each unit is low-cost (8 USD), lightweight (10 kg), compact (15 cm), and robust (e.g., can support 10 kg weight) making it well-suited for prototyping room-scale shape transformations. Moreover, our mod- ular and reconfigurable design allows researchers and designers to quickly construct different geometries and to explore various appli- cations. This paper contributes to the design and implementation of highly extendable inflatable actuators, and demonstrates a range of scenarios that can leverage this modular building block.

LiftTiles: Room-scale Modular Inflatable Actuators

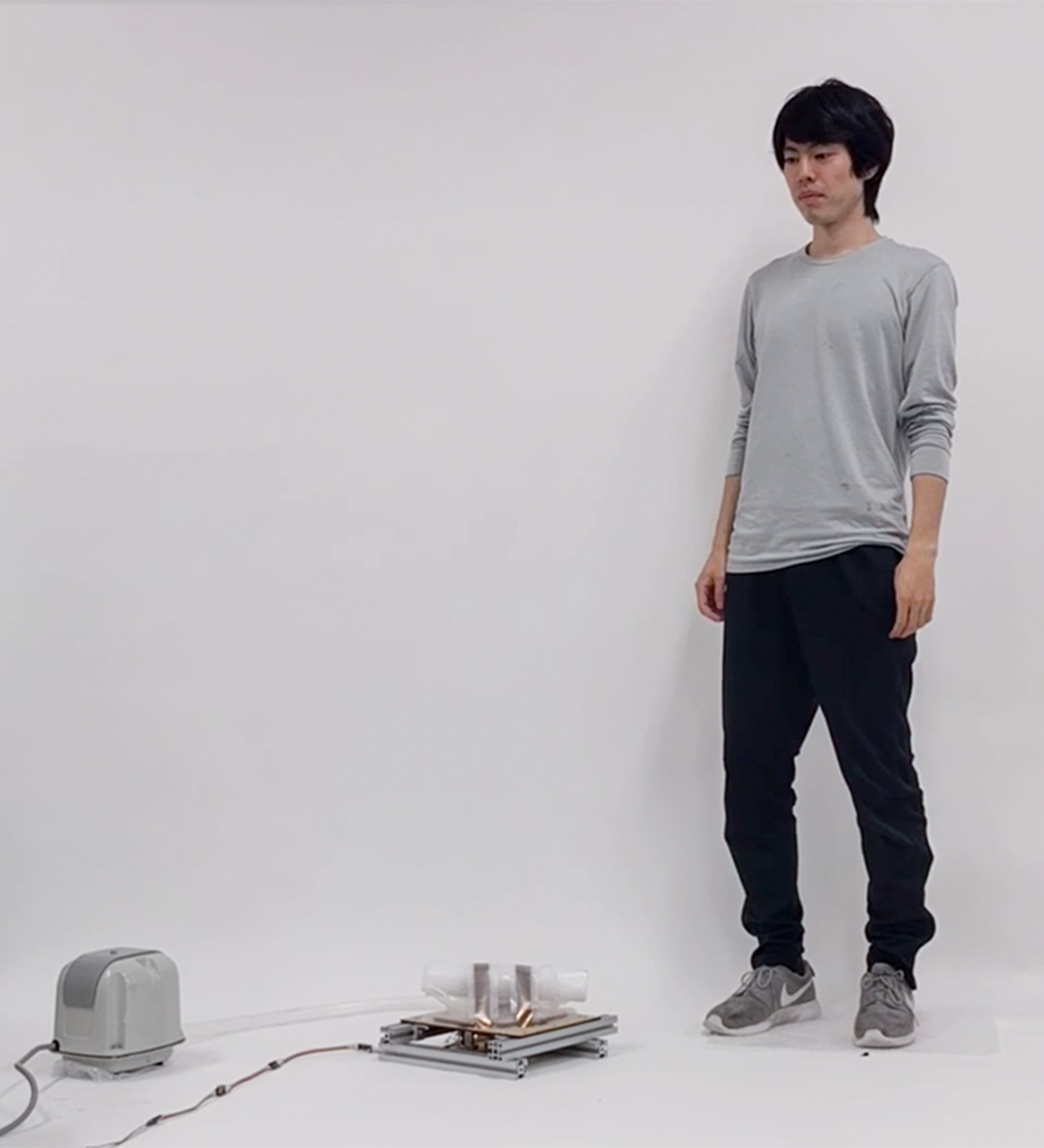

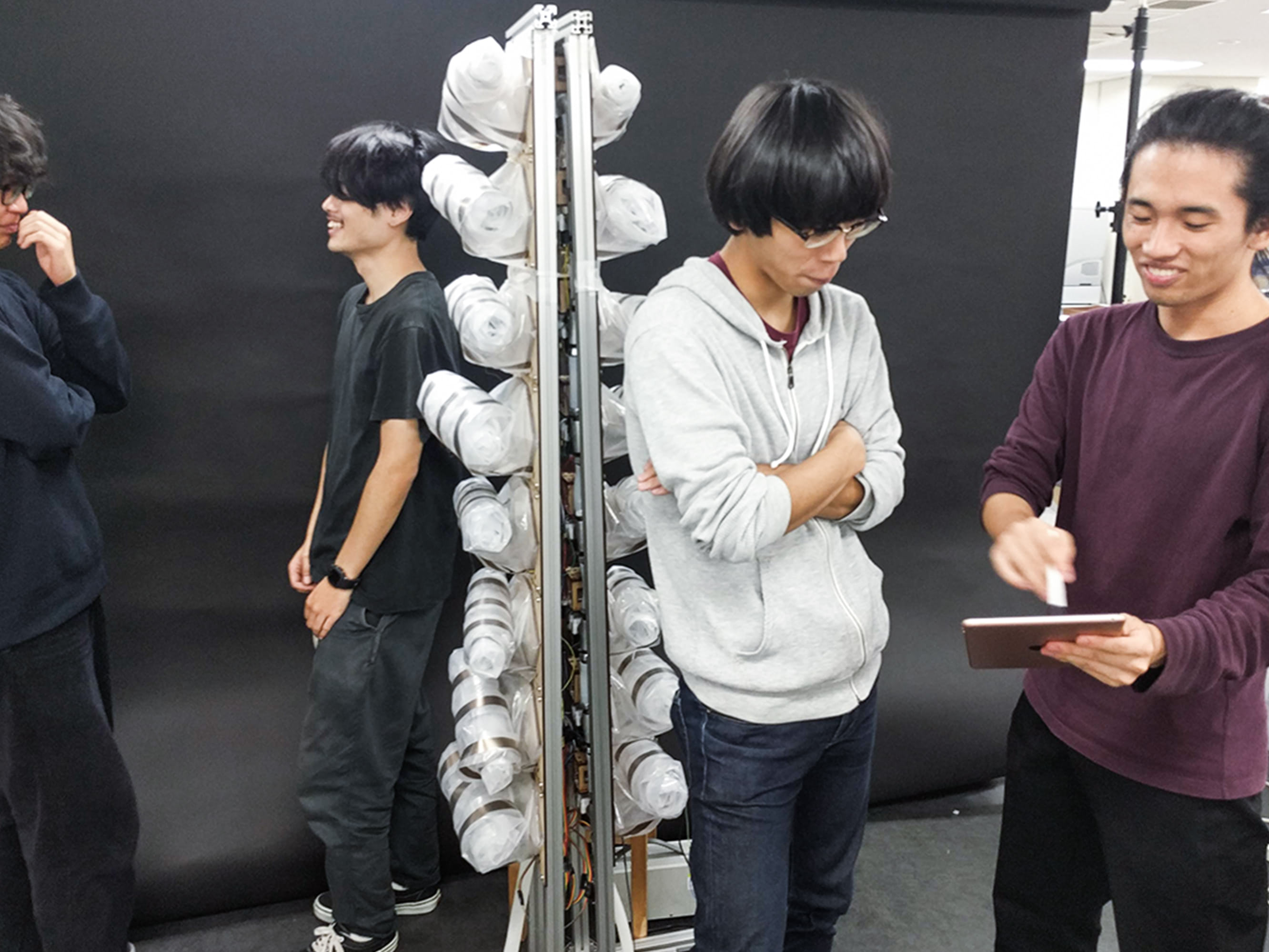

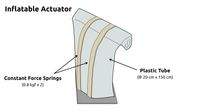

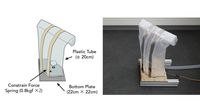

This paper introduces LiftTiles, modular inflatable actuators for prototyping room-scale shape-changing interfaces. Each inflatable actuator has a large footprint (e.g., 30 cm x 30 cm) and enables large-scale shape transformation. The ac- tuator is fabricated from a flexible plastic tube and constant force springs. It extends when inflated and retracts by the force of its spring when deflated. By controlling the internal air volume, the actuator can change its height from 15 cm to 150 cm. We designed each module as low cost (e.g., 8 USD), lightweight (e.g., 1.8kg), and robust (e.g., with- stand more than 10 kg weight), so that it is suitable for rapid prototyping of room-sized interfaces. Our design utilizes constant force springs to provide greater scalability, simplified fabrication, and stronger retraction force, all essential for large-scale shape-change.

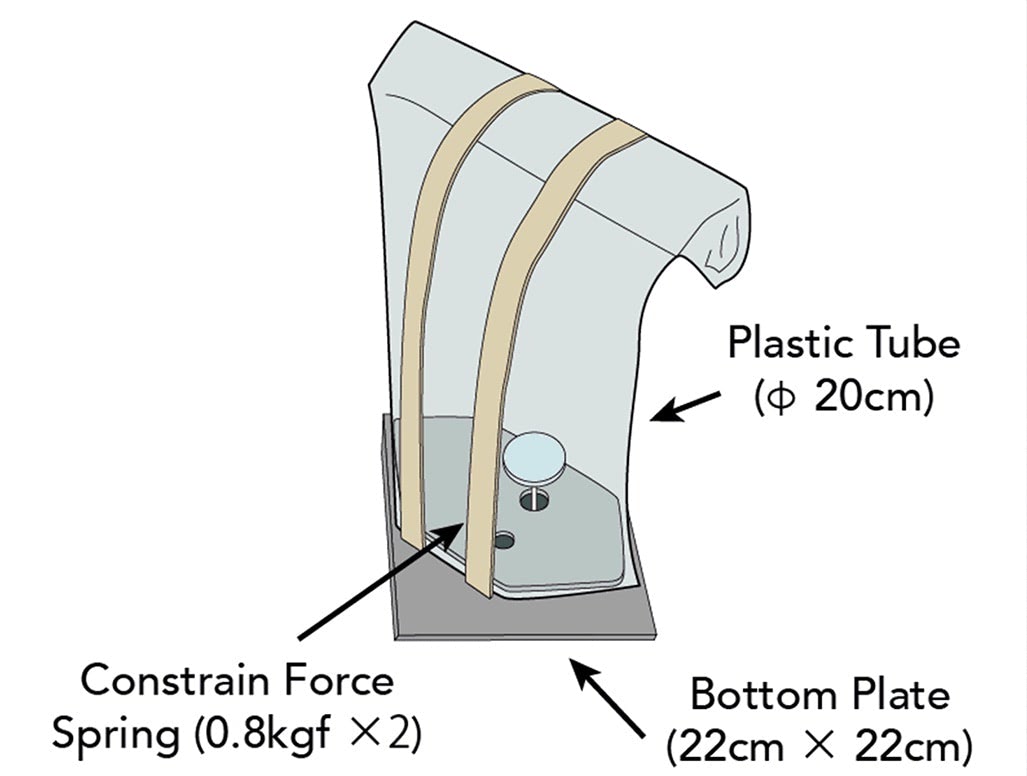

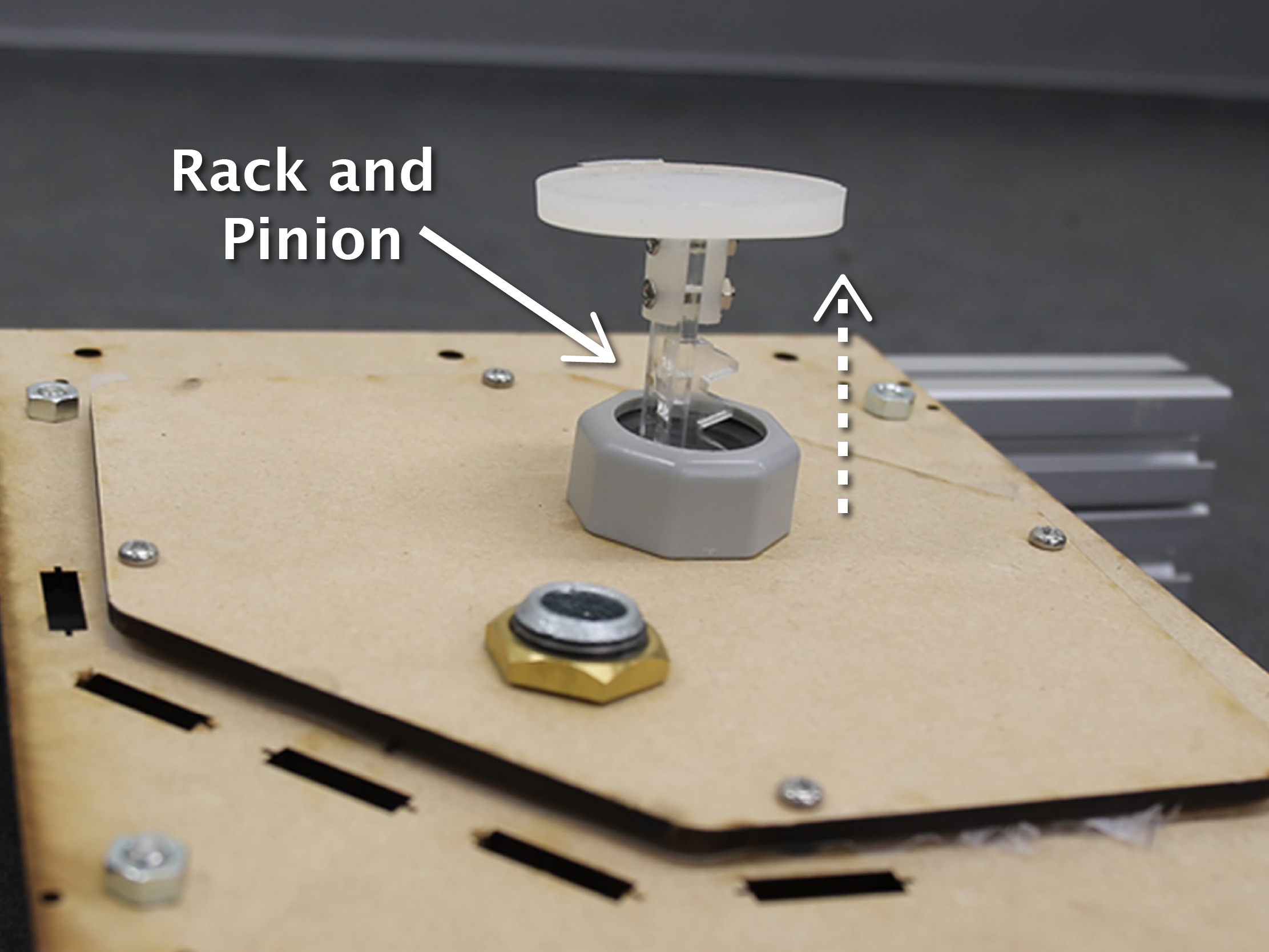

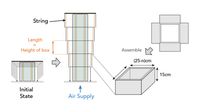

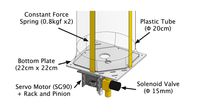

Our inflatable actuator leverages an extendable structure similar to a party horn. Each inflatable actuator consists of a flexible plastic tube and two constant force springs, which are rolled at their resting positions (Figure 2). When pumping air into the tube, the actuator extends as the internal air pressure increases and the end of the tube unwinds. When releasing air through a release valve, the inflatable tube retracts due to the force of the embedded spring returning to its resting position.

The goal of our system is to provide an accessible prototyping building block for room-scale shape-changing interfaces. To achieve this goal, we set the following three design require- ments:

Fast: LIftTiles provide a means to quickly mock up a room-size shape-changing interface

Extendable: range (from 15cm to 150cm),

Low-cost (8 USD per tile),

Light: (10 kg per tile),

Compact: (Each tile compresses to 15 cm)

Modular: (can reconfigure the arrangement)

Strong: (each tile supports up 10 kg)

Modular Design

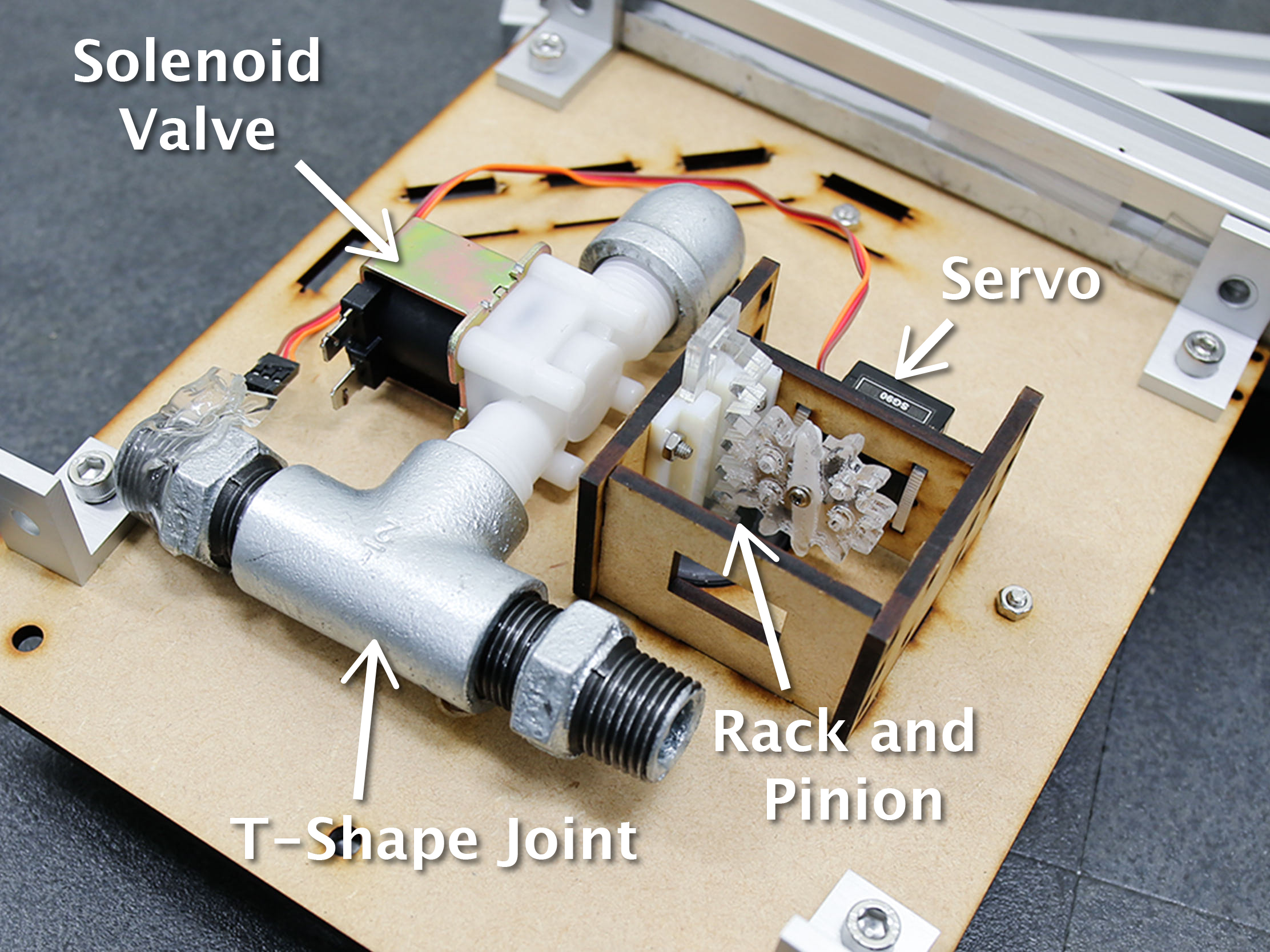

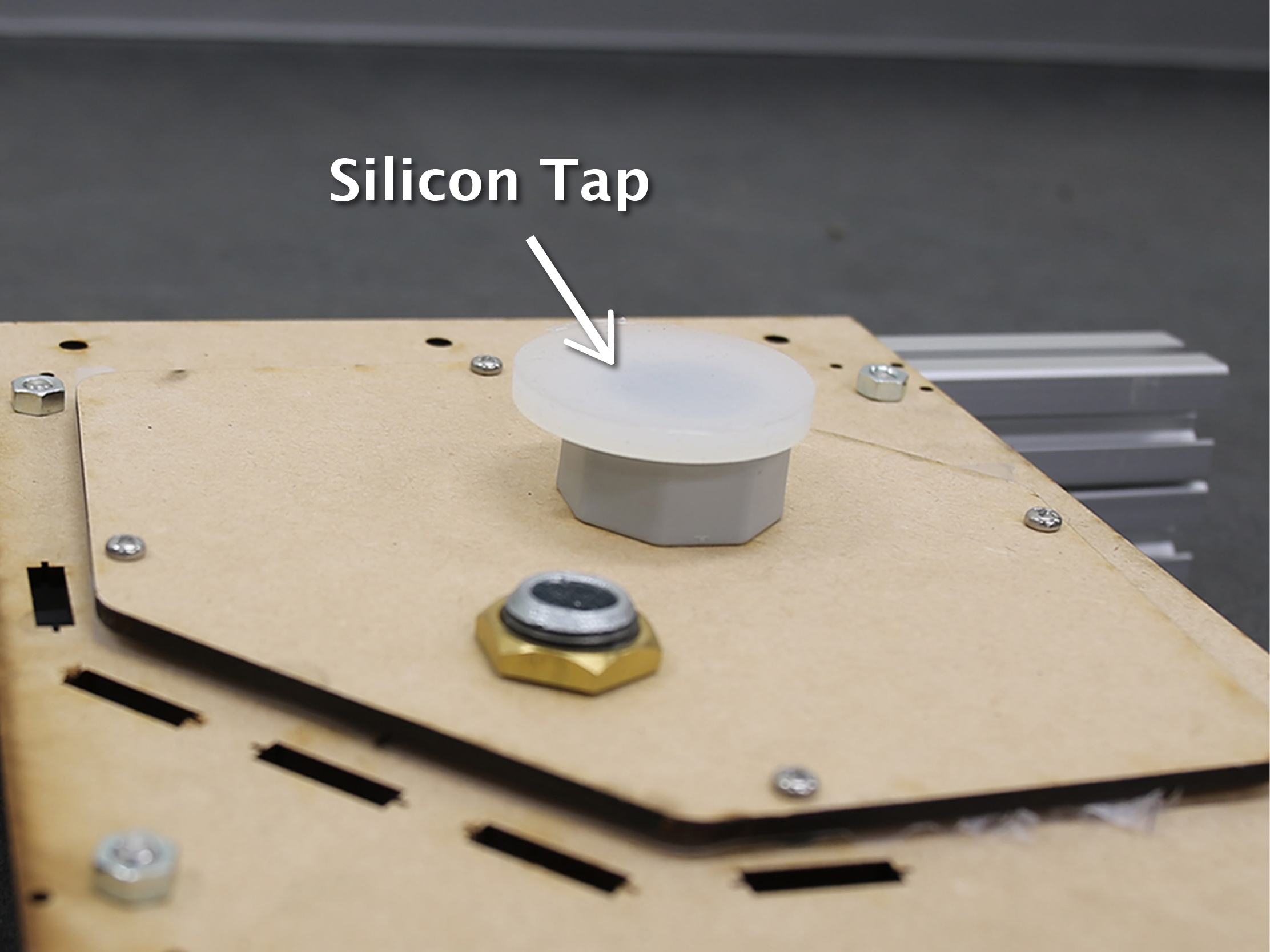

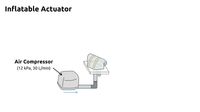

Each actuator is modular and can connect with the air supply of neighboring actuators. Each solenoid air intake valve is connected to a T-fitting. Adjacent actua- tors are pneumatically connected with a silicon tube between the T-fittings (Figure 6). This way, an array of actuators is connected to a shared pressurized supply line.

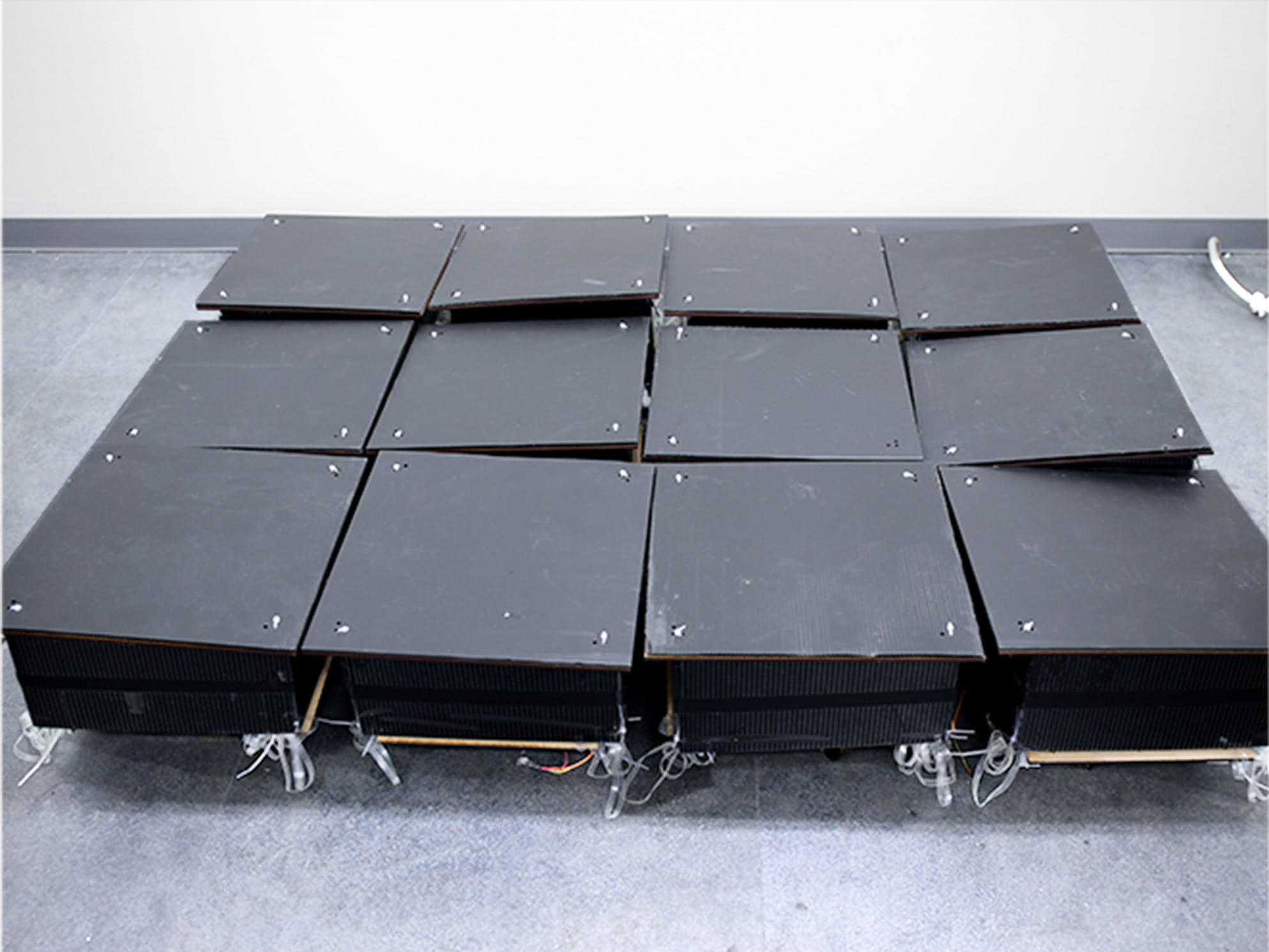

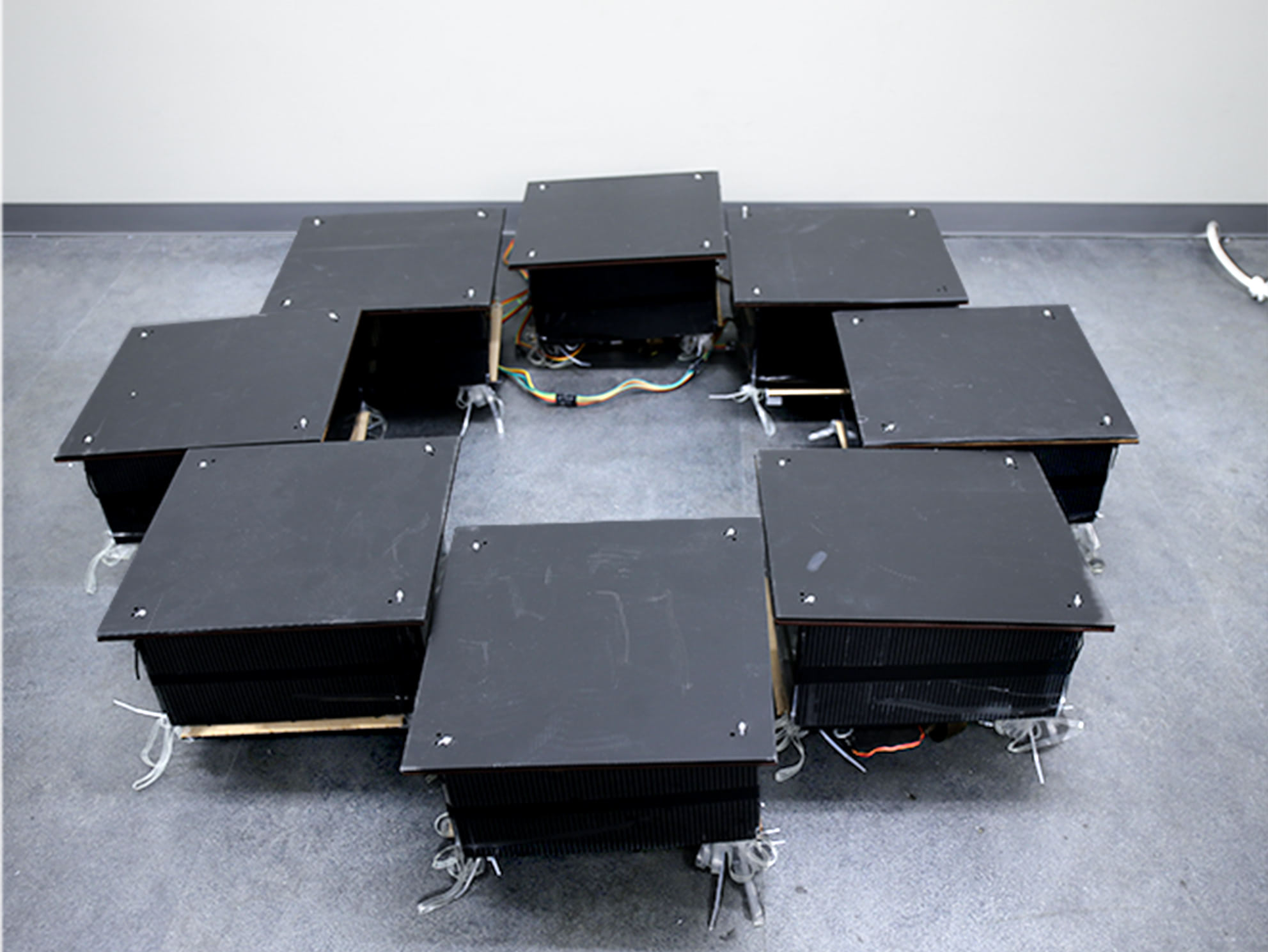

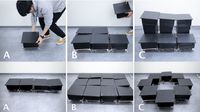

Also, due to the relatively compact size and small weight of the modules, various ar- chitectural surfaces can be considered for installation, such as placed on the floor or installed sideways from a wall. The actuators can be arranged in a grid, a line, or as individ- ual, loosely arranged units. Figure 10 depicts a few example configurations, which can also be reconfigured by the person installing them or the end user. An individual actuator can be picked up and moved, which may let the user handle it like a traditional piece of furniture, but could also open up new possibilities for interaction, such as actuators with a motorized base that reconfigures the arrangement according to the current use case.

Prototyping Applications

To gauge how well LiftTiles is suited to our goal of supporting rapid prototyping and user testing, we built several differ- ent example applications.

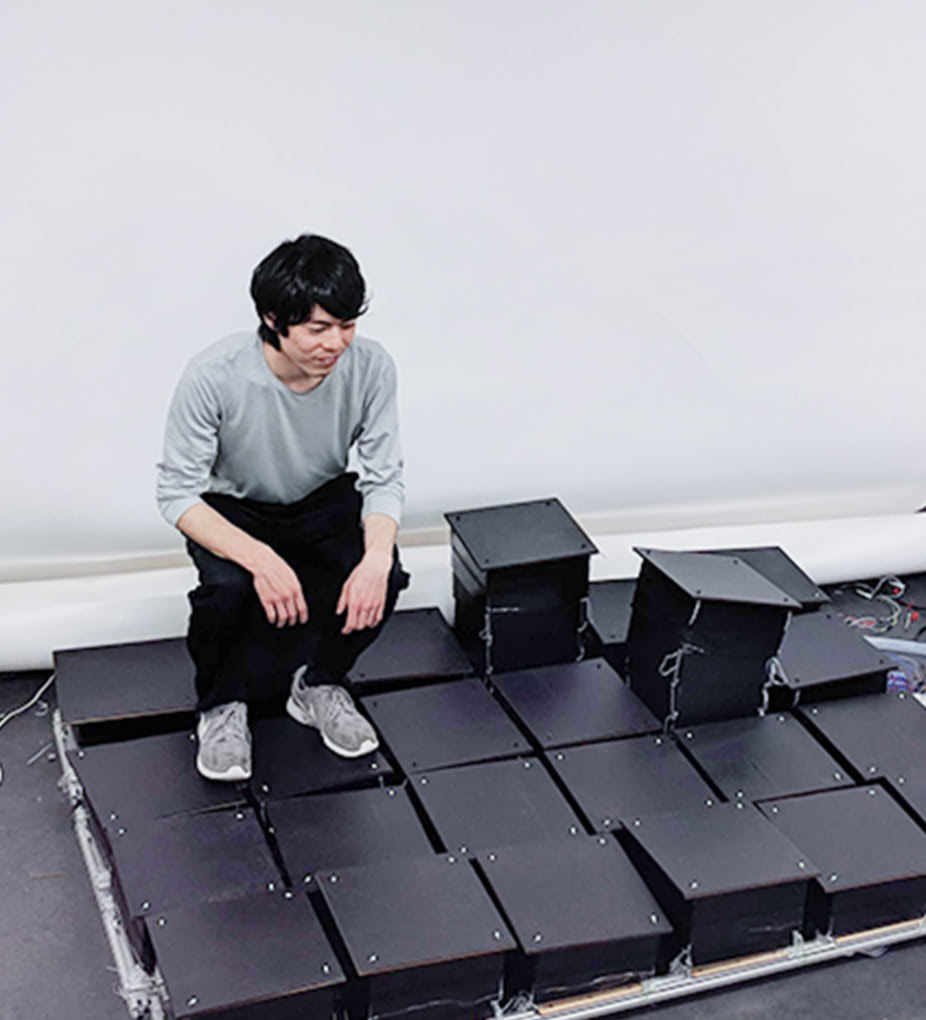

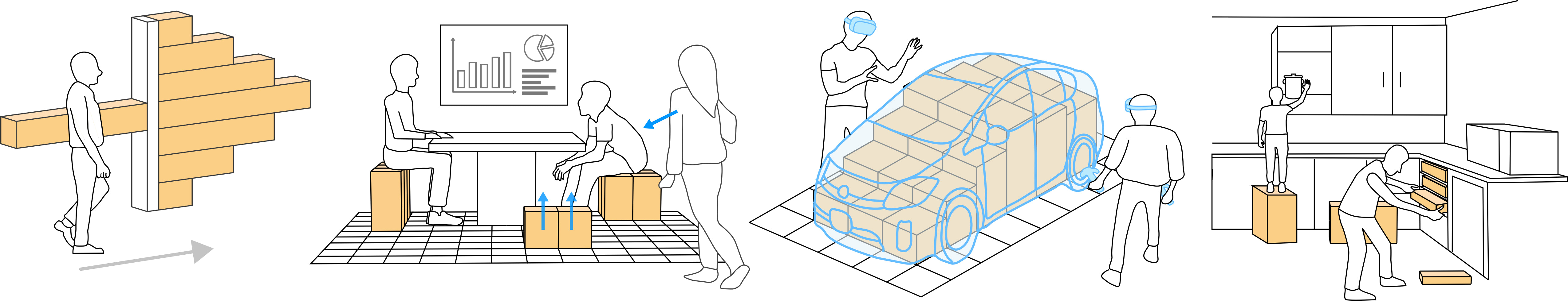

Adaptive Floor Furniture: The first application is a recon- figurable floor that creates adaptive furniture, inspired by an adaptive dynamic table (e.g., TRANSFORM 45) and dy- namic physical affordances (e.g., inFORM 8). We created a shape-changing floor by arranging 25 modules in a 5 x 5 grid. Each unit is individually actuated to provide a chair, a table, and a bed (Figure 1).

Landscape Haptics for VR: While hand-sized shape displays have rendered haptic sensations for VR 34), we propose to render furniture-size props, walls, and game elements that users can feel through walking and touching while experi- encing immersive VR scenes. Similar to the applications pro- posed by HapticTurk 3, TurkDeck 4, and TilePop 44, In this application, the haptics increases the feeling of presence in games by providing room-scale dynamic haptic feedback. Also, this can aid the design process by rendering full-scale object mock-ups of large objects like a car.

Shape-changing Wall: By leveraging the block’s compact form factor, we also prototyped a horizontal shape-changing wall to adapt to user needs and display information. The wall becomes a space separator to make a temporary meet- ing space, while it can also act as public signage by displaying an arrow shape to guide a passer-by.

Deployable Pop-Up Structure: As the actuators are compact compared to traditional furniture and walls, they can be deployed in temporary use cases such as festivals, trade shows, concerts, and disaster relief. In these applications, the actuators are shipped in a compact box and laid out in an empty room, similar to tiles. After connecting them to a compressor and control computer, the operator selects a use case and the blocks render a layout of chairs, beds, tables, and partitions.

Conclusion

This paper introduces constructive building blocks for proto- typing room-scale shape-changing interfaces. To this end, we designed a modular inflatable actuator that is highly extend- able (from 15cm to 150cm), low-cost (8 USD), lightweight (10 kg), compact (15 cm), and strong (e.g., can support 10 kg weight) making it well-suited for prototyping room-scale shape transformations. Moreover, our modular and recon- figurable design allows researchers and designers to quickly construct different geometries and to investigate various ap- plications. In this paper, we contributed to the design and implementation of highly extendable inflatable actuators, and demonstrates a range of scenarios that can leverage this modular building block. We plan to evaluate the potential of our system by inviting designers to use our blocks in their own designs and see whether and/or how our building blocks enhances their ideation process.

Publication

Ryo Suzuki, Ryosuke Nakayama, Dan Liu, Yasuaki Kakehi, Mark D. Gross, and Daniel Leithinger. 2020. LiftTiles: Constructive Building Blocks for Prototyping Room-scale Shape-changing Interfaces. In Proceedings of the 14th ACM International Conference on Tangible, Embedded and Embodied Interaction (TEI '20). ACM, New York, NY, USA, 143–151.

DOI: https://doi.org/10.1145/3374920.3374941

Ryo Suzuki, Ryosuke Nakayama, Dan Liu, Yasuaki Kakehi, Mark D. Gross, and Daniel Leithinger. 2019. LiftTiles: Modular and Reconfigurable Room-scale Shape Displays through Retractable Inflatable Actuators. In Adjunct Proceedings of the 32nd Annual ACM Symposium on User Interface Software and Technology (UIST '19). ACM, New York, NY, USA, 1-3.

DOI: https://doi.org/10.1145/3332167.3357105

Download PDF